The ‘Drawdown’ project at Confidas

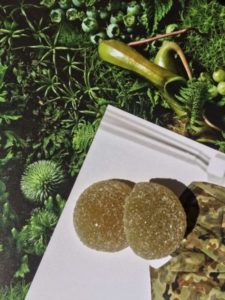

“People often believe that caring for the environment costs a lot of money. That isn’t necessarily so.” Luc Aelterman is the managing director of Confidas, an SME in Ghent that specialises in the production of fruit jellies. He tells us how small companies can make a positive contribution to the environment.

”Drawdown” – the time in the future when the greenhouse gases in the atmosphere stop increasing and gradually start decreasing.

“I am strongly committed to climate issues by nature, and I believe we need to assume our responsibilities. I am looking into the solutions described in the literature. The book Drawdown, by Paul Hawken, has been a great source of inspiration to me.” After Confidas was taken over in 2017, Luc started investigating the areas where they had the greatest impact on the environment and that were easy to address. For Confidas, these areas are energy consumption, waste flows and packaging material.

Energy saving of 40%

“The first thing we tackled was our energy consumption. We wanted to reduce our consumption and looked into alternatives for generating green energy. To do this, we invested in solar panels. This is an attractive investment for our company. After all, we only work in the daytime and our peak production is during the summer months, when the sun shines most. The payback period is also a positive factor. The solar panels pay for themselves within a period of three and a half years. On the one hand, we save on our electricity bill, and on the other we receive payments for our green energy certificates. We are also taking a lot of additional action. For example, lighting is a significant part of our energy bill. That is why we have replaced all our fluorescent lighting with LED lights. It has resulted in an energy saving of 40%!

Then we looked into our fuel oil. In the past, it was used to heat our premises and to generate hot water. We determined the optimal working temperature for the different zones: the warehouse, production lines and office. The temperature in our warehouse used to be 20 degrees. This area is only used for storage of our packaging materials. So it doesn’t need to be warm and cosy. We reduced the temperature to 15 degrees. Furthermore, we couldn’t turn off the heating boiler in the summer months because we needed it to produce hot water. So this year we installed a boiler with a heat pump. Now we always monitor our consumption carefully so that we can adjust it promptly. Unfortunately, our heating boiler is only four years old. If it weren’t, I would replace it with a gas boiler. We do make sure the boiler gets its annual maintenance so that the burners continue to work optimally. After all, poor functioning of the burners leads to higher CO2 emissions.

“We shouldn’t always be looking to big business when it comes to climate change. Small SMEs can do their bit too.”

6 waste flows

Reducing waste is the second aspect that has a great impact on the environment. We currently separate six waste flows: paper and cardboard, plastic containers, plastic film, hard plastic, product waste and non-recyclable waste. Our product waste is sent to a fermentation plant to be turned into biofuel. You do need to find the time to inform your staff about why this is important. After two years, discipline in waste sorting is growing. This year we have also started using the CAO90 bonus arrangements to involve our staff in certain policy decisions, among other things. For example, we set several goals, including waste reduction, for which our staff can earn an end-of-year bonus. They pay reduced tax on this bonus.

Recycled and recyclable packaging

“Last but not least, we attach great importance to how recyclable our packaging is and the proportion of recyclable material in our packaging. Our transparent consumer boxes and lids are all made from PET. This material is recyclable. What is more, we recently started using PET that consists of 40% recycled material. The plastic blisters we use to sort our fruit jellies in the cardboard bulk boxes also contain a high percentage of recycled material.”

“To be honest, our initiatives to slow down global warming are not earth-shattering or innovative”, says Luc, putting things into perspective. “You just extend the way you behave at home to your workplace. You don’t leave the heating on at home without a reason, you turn the lights off when you don’t need them, you sort your waste and you try not to throw away food. We shouldn’t always be looking to big business when it comes to climate change. Small SMEs can do their bit too.”